ESP Insulator Chambers: Penthouse vs. Insulated Box Comparison

In electrostatic precipitators (ESPs), the stability of the insulator environment is critical to overall system performance. Temperature fluctuations, moisture ingress, or poor accessibility can all compromise the insulation quality and operational safety of the ESP.

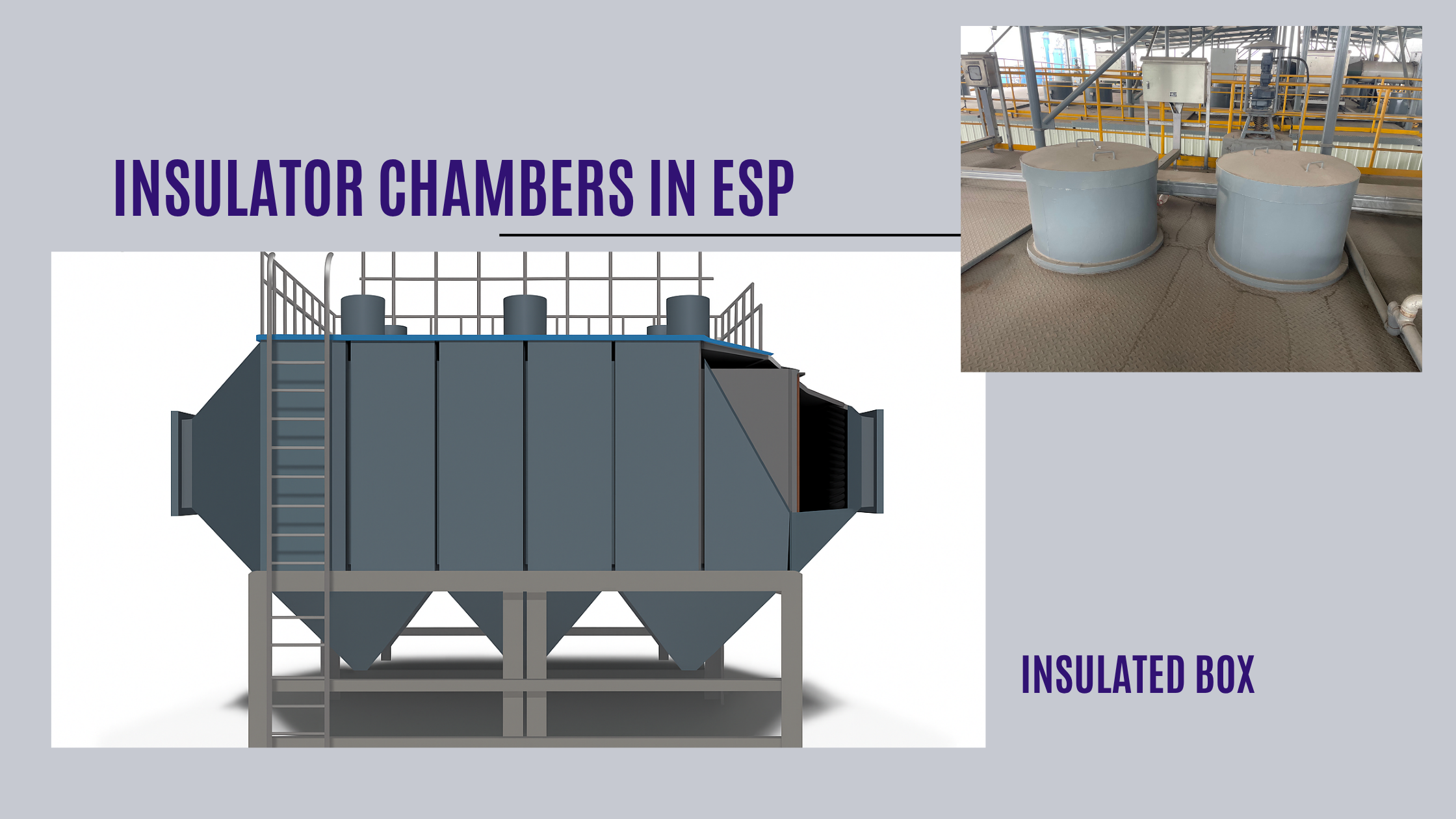

Two major design approaches are used to house insulators:

- Penthouse structure

- Insulated box structure

While both serve the same functional goal—maintaining a stable environment for the insulators—they differ significantly in layout, maintenance, and long-term reliability. This article offers a balanced comparison and explains why, despite certain trade-offs, the penthouse structure often offers superior long-term value.

1. Structural and Operational Principles

Penthouse Structure

- Configuration: Installed above the ESP roof as an integrated, walk-in enclosure with a sloped top (~1.2°) for water drainage.

- Components: Hosts all rigitrode support insulators, rapper motors, rectifier transformers, isolating switches, and hot air equipment.

- Access: Entry hatch and internal clearance (~1700 mm) allow direct walk-in inspection.

Operation: Uses centralized heating and temperature control for a stable insulator environment.

Insulated Box Structure

- Configuration: Individual sealed boxes mounted on the ESP shell; double-layer metal casing with insulation wool inside.

- Components: Each box contains one or more insulators, along with hot air cleaning and monitoring equipment.

- Access: Maintenance requires opening each box individually.

Operation: Uses distributed heating via pipelines; sealing integrity is essential to prevent cold air ingress.

2. Maintenance Comparison: Where Penthouse Excels

Key Advantages of Penthouse Design

✅ Walk-In Accessibility

Engineers can perform inspections and maintenance without dismantling multiple units. Everything is visible in one centralized space.

✅ Fewer Failure Points

No need for dozens of access doors, gaskets, or pipe connections—reducing leak risks, sealing issues, and long-term corrosion.

✅ Faster Troubleshooting

All components are co-located, allowing batch inspections and simplified fault tracing.

✅ Efficient Hot Air Control

Centralized temperature regulation ensures uniform heating, improving insulation stability and reducing energy waste.

3. Trade-Offs: What to Watch Out For with Penthouse Design

Even with its many strengths, the penthouse design introduces some challenges:

- Structural Weight: Larger internal volume and roof-mounted equipment increase load requirements; may not suit retrofits or lightweight ESPs.

- Fabrication Complexity: Larger steel structures and insulation lining add upfront manufacturing and installation cost.

- Thermal Expansion Risk: Exposure to hot flue gas may cause material stress if expansion allowances are not built in—especially on sidewalls or roof seams.

💡 However, with proper design detailing (e.g., expansion joints, reinforced seams), these issues are manageable and preventable.

4. Insulated Box Design: Strengths and Limitations

Strengths:

- Lighter and modular—easier to install on small-scale or segmented ESPs

- Scalable across distributed systems

- Lower material cost per unit

Limitations:

- 🔧 Maintenance-intensive: Each box must be opened and serviced independently, increasing time and labor costs

- 🧯 Risk of leaks: Gaskets are exposed to high heat and can degrade over time

- ⚡ Inconsistent heating: Pipeline distribution can lead to uneven temperature across chambers

- 💸 Higher lifecycle cost: Though cheaper to build, long-term maintenance is more demanding

5. Conclusion: Making the Smart Choice for Your ESP

When ease of maintenance, system integration, and long-term performance matter, the penthouse structure provides clear operational advantages—especially for large-scale ESPs with top-mounted rapping systems.

It reduces inspection time, consolidates fault response, and improves overall system durability.

Yes, it requires careful structural planning and comes with higher initial investment. But for many operators, that investment is repaid many times over in reduced downtime, fewer failure events, and lower lifecycle maintenance costs.